-

1. Any Carbon Fiber Product is A "Blend"

Well, when I say a "blend", what I really mean is that it's a "composite material" made from several blended elements. And it's very common for people to think that it's a pure substance given its name rather than a composite material.

Raw carbon fiber is actually quite brittle and prone to cracking and splitting even though it is remarkably stiff when used to make something. To make the carbon fiber stiff, it is blended with epoxy resin before being molded into the shape of the product.

It's this important combination of elements, the carbon fiber and the epoxy resin, that gives carbon fiber it's stiffness and ultimately a strong finished product.

-

2. The Stiffness of the Carbon Fiber Can be Manipulated

So, you are probably familiar with the fact that in its final composite state carbon fiber is very stiff.

But, I bet you didn't know that this stiffness can be controlled.

You see, the fibers are strong in one direction (unidirectionally) along the length of the fiber and with a mix of certain carbon fibers the stiffness can be controlled quite precisely.

What is even more amazing is that a carbon fiber composite can become flexible by as much as 88% as the temperature is increased but will completely recover to it's original state when the heat is removed.

-

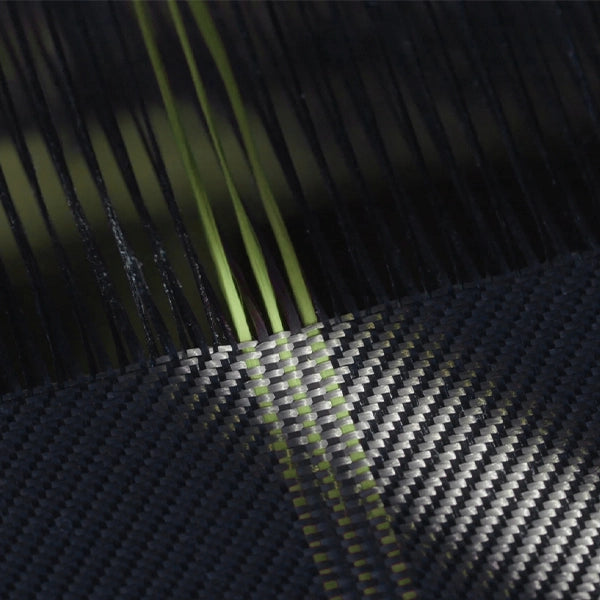

3. Carbon Fibers: More Than Twill Weave

The most common weave that you will see used in carbon fiber products is the twill weave and it's typical for people to think that it's the only weave available.

However, as I mentioned in a previous post, carbon fiber cloth is woven along the fiber orientation to create both the plain weave and the twill weave.

The plain weave is less pliable and more abrasion-resistant, whilst the twill weave has fibers that run straighter and longer, maintaining the theoretical strength of the carbon fiber as well as making it stronger and more pliable than the plain weave.

There are a few other less well known weaves out there, "satin" weave, "harness" weave and even "fish" weave. These are all different patterns that are used for specific purposes and not so widely utilized.

The "harness satin" weave is an even more flexible fabric. It is very well suited to conforming to complex curves, typical seen in reinforced plastics.

-

4. There is Even "Wet" Carbon Fiber Cloth

Carbon fiber cloth comes in two forms, commonly known as wet prepreg cloth and dry prepreg cloth.

Wet prepreg cloth is easier to work with and it is commonly used to make automotive products such as front lip spoilers, rear diffusers and boot spoilers. A manufacturer can make wet prepreg cloth by pouring a precise amount of epoxy resin over the carbon fiber cloth.

Dry prepreg cloth which is otherwise known as "Dry Carbon" is similar to wet prepreg in that they both use epoxy resin to bond together the carbon fiber fabric. The difference is down to the epoxy resin used in dry prepreg, this has specific "dry" properties when it is infused into the cloth.

Dry prepreg cloth is typically more expensive than the wet cloth because of the manufacturing process as well as the more advanced resins used.

-

5. Carbon Fiber Filaments are Countable (Even If Your Own Hair is Not)

If you happened to look for data on carbon fiber, you will often come across the letter "K" in its description, you will see it alongside a number such as 1K, 3K and 12K.

But what does this "K" mean?

Well, if you look at any woven cloth, e.g. twill weave, you will see that it is woven from bunches of carbon fiber filament known as rovings.

Each roving is actually a collection of individual carbon fibers and the "K" number relates to how many fibers are present in the roving.

So, if you see a "K" rating such as 3K, this means that the rovings used to weave the cloth are made from 3000 individual fibers, whilst a 12K rating means that the roving is woven from 12,000 individual fibers.

-

6. Carbon Fiber's Secret to Increased Stiffness

Maybe you've heard about UD carbon fiber fabrics.

UD is short for unidirectional and as the name suggests, this means that all the filaments lay in parallel in one direction without crossing or weaving over each other.

Now, in this instance, the "K" rating, 1K, 3K and 12K is not that relevant any more. Something quite often ignored by marketing people.

UD is different from other woven fabrics in that it has a different appearance and different mechanical properties.

UD reinforcement makes it possible to create incredibly strong, light components by precisely orienting the carbon fiber to provide maximum strength in the direction where it is needed most.

-

7. Carbon Fiber is Older Than You Thought..

Carbon fiber was initially created by Joseph Swan and used in light bulbs way back in the 1860s.

But the more familiar high performance carbon fibers were invented by Roger Bacon in 1958 at the Union Carbide Parma Technical Center (now GrafTech International Holidays, Inc.) located outside of Cleveland, Ohio.

It was not until a new manufacturing process was developed at a British research center in 1963 that carbon fiber's strength potential was fully realized. The process was developed by W. Watt, L. N. Phillips, and W. Johnson at the Royal Aircraft Establishment at Farnborough, Hampshire.

It was then licensed by the National Research Development Corporation to three British companies, Rolls-Royce, Morganite and Courtaulds.

-

8. Carbon Manufacturing is More Complicated and Costly Than You Can Imagine

Manufacturing carbon fiber used to be slow and inefficient, making it quite costly to use in mass production.

Fortunately, through advancement in technologies and processes, the cost has come down considerably which has meant that it has moved carbon fiber into mainstream manufacturing.

It is still reassuringly expensive though.

-

9. Carbon Fibers are Made from Petroleum And...

The raw material used to produce carbon fiber is called precursor. Amongst these precursors, 90% of the carbon fibers are made from polyacrylonitrile (PAN) with the remaining 10% made from rayon or petroleum pitch.

All of these are organic polymers, which feature long strings of molecules bound together by carbon atoms.

Different precursors are used to make different carbon fibers, and the resulting ones could be turbostratic or graphitic, or have a hybrid structure with both graphitic and turbostratic parts.

-

10. Most Raw Carbon Comes from Asia

There are only a few companies in the world that actually have all the technical capabilities to manufacture the raw carbon fiber itself, even though technology has improved things, it's still a very complicated process.

According to a 2010 report on the carbon fiber market by US Department of Energy report, over 90% carbon fiber supply comes from just six companies: Toray, Toho Tenax, Mitsubishi Rayon, Zoltek, Hexcel and Cytec.

The first three in the list are all Asian companies and account for nearly two-thirds of the global carbon fiber production. The latter three are headquartered in the US, taking up less then one-third of the world's carbon fiber production.

-

11. Carbon Fiber Products Can be Repaired

Many will think that once a carbon fiber product has been damaged, it's toast, but this is not entirely true. Many carbon fiber products can actually be repaired successfully just like steel-made or titanium-made products.

However, it's not easy though and is best left to the experts. Do not try it at home as you will probably end up with a mess, so leave it to the manufacturers as they probably have an in-house perfect repair team.

-

12. Higher Modulus Carbon Fiber Doesn't Mean Higher Quality

Modulus refers to the stiffness of the fibers that are woven into sheets of carbon fiber.

So as you go from a standard modulus fiber right through to ultra-high modulus, the fibers get stiffer, lighter and more expensive to manufacturer.

Quite often you will find some marketing information trying to sell you a carbon fiber product made from ultra-high modulus carbon fiber.

But the truth of the matter is that however expensive your carbon fiber products is, you always need a mix of fibers.

Let me explain it like this.

Take a mountain or road bike for example. If the manufacturer were to make the bike out of high-modulus carbon fiber, it will be super light but it will also be uncomfortably stiff and brittle.

So, the art of producing a wonderful carbon fiber product is to get the right mix of fibers and to ensure that the end products has all the right characteristics.

-

13. Will Sunlight Weaken Carbon Fibers?

Even though the carbon fibers themselves are not susceptible to UV damage, the resin used to bond carbon fibers together can be, meaning that your carbon fiber parts or frames could degrade over time, "in theory".

Fortunately, carbon fiber manufacturers understand this problem, so they will often use UV-resistant resins and finish the surfaces off with UV protective lacquers meaning that you don't need to worry any more.

-

14. Carbon Fiber is Naturally RFID-blocking and It Will Kill Your Cell Phone Signal

Yes, unfortunately that is true. I mentioned it in one of my previous posts - Carbon Fiber Phone Cases: "Just Say No".

Because the carbon fiber is a conductor of electricity and magnetism, it will affect the signal of your mobile phones.

Carbon fiber has been proven to dramatically reduce your phone cellular signal reception via Radio Frequency Interference (RFI). Carbon fiber phone cases have been shown to reduce the average cellular signal by as much as 40%-60% and aluminum and other similar metal phone cases don't do much better and can reduce your signal strength in a similar way.

-

15. Carbon Fiber is Being Used in More Places Than You Might Think.

It's true, carbon fiber is everywhere and I mean everywhere. You may have a carbon fiber bike at your home or your friend is holding a carbon fiber wallet in their hand.

Over time, carbon fiber has played an increasingly important role in many different walks of life.

Aerospace: Carbon fiber has been to moon on Spacecraft. It has been made into aircraft components and structures. From helicopters to gliders, fighter jets to microlights, carbon fiber is playing an increasingly important role and enabling aircraft to be made lighter and stronger.

Sporting Goods: You may be wearing a pair of running shoes with carbon fiber built in. Its application on sporting equipment ranges from tennis racquets to golf clubs.

Automobile: BMW uses a lot of carbon fiber in the manufacturing of its cars, from the interior trim parts to exterior parts such as spoilers, bonnets and even roofs. More and more manufacturers are starting to see this as an extremely versatile material, e.g. Tesla, Rolls Royce, Ferrari and Lamborghini to name but a few.

Medical: Carbon fiber is being increasingly used in the manufacturing of medical prosthetics and helping people to lead healthy lives once more. It's combination of lightweight and strength means that limbs can be made in such as way that would be unheard of 10 years ago.

...

The list could go on and on and it just goes to show that carbon fiber is appearing in all walks of life in an unstoppable way.

Perhaps this is just one reason why carbon fiber is popular with the tech heads out there.